, WANG Wei-shan2 , SHI Ming-xin2 , YANG Ke-qian2

, WANG Wei-shan2 , SHI Ming-xin2 , YANG Ke-qian2

2. State Key Laboratory of Microbial Resources, Institute of Microbiology, Chinese Academy of Sciences, Beijing 100101, China

链霉菌能产生多种具有生物活性的次级代谢产物,如抗生素、免疫抑制剂、杀虫剂等,其中尤以产抗生素药物的能力最为突出。早期链霉菌发酵产品的开发主要是筛选天然的高产菌株,提高链霉菌发酵能力的研发主要集中在通过化学诱变和大批量随机筛选技术来获得发酵能力提高的突变菌株。而近20年来以代谢工程(metabolic engineering)为手段的理性改造工程菌株的发展势头变得更加强劲,特别是在系统生物学迅速发展的今天,各种组学和生物信息学方法为菌株改造提供了强大的分析手段,因此代谢工程手段改造微生物工程菌株被人们寄予厚望[1-2]。代谢工程技术是指利用DNA重组技术对工程菌株进行修饰和改造,协调微生物的初级和次级代谢途径,使之合成目标产物的量大幅度提高,代谢工程技术对微生物发酵工业的发展起到极大的推动作用[1, 3]。本文主要是运用代谢工程手段对土霉素的生产菌株进行工程改造,在相同的发酵条件下大幅度提高土霉素的产量。

链霉菌次级代谢产物的合成受到多种调控因子的调节,其中途径特异性调控因子(pathway-specific regulator)是次级代谢产物合成最基础的执行者,由于该类调控基因通常与次级代谢合成基因簇紧邻或排列在其内部,谭华荣研究员课题组也将其命名为簇内调控因子(cluster-situated regulator, CSR)[4]。途径特异性的调控因子能够直接识别和启动抗生素合成基因簇的转录和表达,过表达途径特异性调控因子可显著促进次级代谢产物的合成。例如,过表达途径特异性调控蛋白RedD和ActII-ORF4导致天蓝色链霉菌(Streptomyces coelicolor)中十一烷基灵菌红素(undecylprodigiosin,RED)和放线紫红素(actinorhodin,ACT)产量提高[5-6];过表达CcaR使棒状链霉菌(Streptomyces clavuligerus)合成克拉维酸(clavulanic acid)的产量提高了3倍[7-8]。除了强化途径特异性调控蛋白表达能够大幅度提高次级代谢产物的产量外,增加链霉菌次级代谢产物的合成所需的前体物或底物的量,也能够显著提高次级代谢产物的产量。合成次级代谢产物的前体一般是初级代谢物,如核酸、氨基酸、脂肪酸代谢、糖酵解和三羧酸循环(tricarboxylic acid cycle,TCA)等途径的中间产物。例如,在葡萄糖代谢中,糖酵解和磷酸戊糖途径相互交织成网络,敲除磷酸戊糖途径中的某个葡萄糖-6-磷酸脱氢酶(glucose-6-phosphate dehydrogenase,G6PDH)基因zwf1或zwf2,使碳源更多的流向糖酵解途径,从而大量积累前体物乙酰辅酶A(acetyl-CoA)和丙二酸单酰辅酶A(malonyl-CoA)。Butler等[9]利用该手段在变铅青链霉菌(Streptomyces lividans)宿主内敲除zwf1或zwf2基因使得ACT和RED的产量大幅度提高;土霉素(oxytetracycline,OTC)合成的前体物为丙二酸单酰辅酶A,郭美锦等在土霉素生产菌株龟裂链霉菌(Streptomyces rimosus)宿主内敲除zwf1或zwf2同样也能使土霉素产量得到显著提高[10-11]。

土霉素是四环素类的广谱抗生素,对革兰氏阳性菌、革兰氏阴性菌、支原体等引起的感染性均有疗效。尽管近些年来临床上细菌耐药性不断蔓延[12],但土霉素在畜牧业、水产养殖及其它领域仍具有广泛的应用。同时,土霉素可作为合成强力霉素(或称为脱氧土霉素,doxycycline)及美它环素(或称为甲烯土霉素,methacycline)等二代四环素的一种原料药[13],而强力霉素和美它环素在临床上具有非常广泛的应用价值,因此土霉素仍然具有良好的市场前景[14-15]。龟裂链霉菌是土霉素的产生菌,本文主要采用两种策略对龟裂链霉菌M4018进行工程改造来提高其土霉素产量:首先尝试选择不同转录强度的启动子及两个或三个启动子的串联组合来过表达土霉素合成途径的特异性激活子OtcR,使土霉素的产量提高到原菌株产量的4倍;在此基础上,进一步增强乙酰辅酶A羧化酶表达,使初级代谢产生的乙酰辅酶A更多的转化为丙二酸单酰辅酶A,增加合成土霉素的前体物,最终使土霉素产量提高到原来的6.6倍。本文对以代谢工程手段改造工业菌株,提高龟裂链霉菌土霉素的产量具有一定的指导意义。

1 材料与方法 1.1 材料1.1.1 试剂

土霉素标准品(CAS号6153-64-6)、三氯化铁、卡那霉素、硫酸安普霉素、氯霉素和萘啶酮酸等均购自上海阿拉丁生化科技股份有限公司;丙二酸单酰辅酶A标准品购自Sigma公司;限制性内切核酸酶(New England Biolabs)、T4 DNA聚合酶(New England Biolabs)、T4 DNA连接酶(New England Biolabs)和Q5® High-Fidelity DNA聚合酶(New England Biolabs)均购自北京百灵克生物科技有限公司;质粒提取及DNA琼脂糖凝胶回收试剂盒均购自北京博迈德基因技术有限公司。

1.1.2 菌株及培养基

本实验所用土霉素生产菌株为S. rimosus M4018(源于辉瑞制药),本实验构建的所有突变株均以M4018为出发株,克隆菌株为E.coli Top10(Invitrogen),链霉菌接合转移供体菌为E.coli ET12567/pUZ8002[16],其它过表达突变株见表 1。

| Name | Description | Sources |

| Streptomyces | ||

| Streptomyces rimosus M4018 | A strain used for commercial production of OTC | Iain Hunter |

| Streptomyces coelicolor M145 | Template containing accA2BE | [6] |

| M4018/pSF14otcR | Integrated a copy of SF14-driven otcR in the genome of M4018 | This study |

| M4018/PermE*otcR | Integrated a copy of PermE*-driven otcR in the genome of M4018 | This study |

| M4018/pkasO*otcR | Integrated a copy of PkasO*-driven otcR in the genome of M4018 | This study |

| M4018/pESotcR | Integrated a copy of ES-driven otcR in the genome of M4018 | This study |

| M4018/pKESotcR | Integrated a copy of KES-driven otcR in the genome of M4018 | This study |

| M4018/GT | Integrated a control plasmid pGT in the genome of M4018 | This study |

| M4018/pSF14GFP | Integrated a copy of SF14-driven gfp in the genome of M4018 | This study |

| M4018/PermE*GFP | Integrated a copy of PermE*-driven gfp in the genome of M4018 | This study |

| M4018/pkasO*GFP | Integrated a copy of PkasO*-driven gfp in the genome of M4018 | This study |

| M4018/pESGFP | Integrated a copy of ES-driven gfp in the genome of M4018 | This study |

| M4018/pKESGFP | Integrated a copy of KES-driven gfp in the genome of M4018 | This study |

| M4018/KaccA2BE | Integrated a copy of KES-driven accA2BE in the genome of M4018 | This study |

| M4018/KotcR-KaccA2BE | Integrated a copy of KES-driven otcR and accA2BE in the genome of M4018 | This study |

| Escherichia coli | ||

| TOP10 | General cloning host for plasmid manipulation | Novagen |

| ET12567 (pUZ8002) | Donor strain for conjugation between E. coli and Streptomycetes | [16] |

| Plasmids | ||

| pGusT-SF14 | Conjugative, integrative vector derived from pSET152, containing | |

| SF14-driven gusA AmR, lacZ, reppMB1 attФC31, oriT | [17] | |

| pSF14-GFP | Derived from pGusT-SF14, containing SF14-driven gfp | [17] |

| pGT | Derived from pSF14-GFP, deleting the SF14 promoter | This study |

| pSF14-otcR | Derived from pGusT-SF14, SF14-driven otcR | This study |

| pDR4-E | Template containing the PermE* promoter | This study |

| pDR4-K* | Template containing the PkasO* promoter | This study |

| PermE*-otcR | Derived from pSF14-otcR, PermE*-driven otcR | This study |

| pkasO*-otcR | Derived from pSF14-otcR, PkasO*-driven otcR | This study |

| pES-otcR | Derived from pSF14-otcR, PkasO*-PermE*-SF14driven otcR | This study |

| pKES-otcR | Derived from pSF14-otcR, PkasO*-PermE*-SF14driven otcR | This study |

| permE*-gfp | Derived from permE*-otcR, PermE*-driven gfp | This study |

| pkasO*-gfp | Derived from pkasO*-otcR, PkasO*-driven gfp | This study |

| pES-gfp | Derived from pES-otcR, PermE*-SF14-driven gfp | This study |

| pKES-gfp | Derived from pKES-otcR, PkasO*-PermE*-SF14driven gfp | This study |

| pKaccA2BE | Derived from pkasO*-otcR, PkasO*-driven accA2BE | This study |

| pKotcR-KaccA2BE | Derived from pkasO*-otcR, PkasO*-driven otcR and PkasO*-driven accA2BE | This study |

LB培养基:胰蛋白胨10g/L、酵母提取物5g/L、氯化钠10g/L,pH7.0,固体培养基中加入20g/L琼脂粉;2×YT培养基:胰蛋白胨16g/L、酵母粉10g/L、NaCl 5g/L,pH7.0;MS培养基:甘露醇20g/L、大豆粉20g/L、琼脂粉20g/L;R5培养基:蔗糖103g/L、MgCl2·6H2O 10.12g/L、K2SO4 0.25g/L、葡萄糖10g/L、微量元素溶液2ml/L、酪蛋白氨基酸0.1g/L、酵母粉5g/L、TES缓冲液(5.73%, pH7.2)100ml/L,115℃、1.01×105Pa灭菌30min。使用前加入灭过菌的下列溶液:KH2PO4(0.5%)10ml/L,CaCl2·2H2O(5mol/L)4ml/L,NaOH(1mol/L)7ml/L,L-脯氨酸(20%)15ml/L;种子培养基配方[17]:淀粉30g/L、黄豆饼粉3g/L、硫酸铵4g/L、碳酸钙5g/L、玉米浆4g/L、氯化钠5g/L、磷酸二氢钾0.15g/L;发酵培养基配方[18]:淀粉150g/L、黄豆饼粉20g/L、硫酸铵14g/L、碳酸钙14g/L、氯化钠4g/L、玉米浆4g/L、磷酸二氢钾0.1g/L、氯化钴10μg/L、淀粉酶0.1%~0.2%。上述培养基灭菌条件:121℃、1.01×105Pa灭菌30min。

1.2 方法1.2.1 质粒构建

本实验所用PCR扩增模板及引物序列如表 1和表 2所示。出发质粒pSF-otcR经BglII和BamHI双酶切获得骨架片段,分别以pDR4-E和pDR4-K*[19]为模板扩增permE*和PkasO*启动子序列,该启动子序列经BglII和BamHI双酶切后与上述骨架片段相连得到PermE*-otcR和PkasO*-otcR;以pGusT-SF14为模板(引物ES-F/R)扩增SF14启动子序列,该片段经BamHI酶切并与经相同限制性内切酶酶切的PermE*-otcR骨架片段连接得到pES-otcR;以pDR4-K*为模板扩增PkasO*启动子序列,该片段经BglII酶切,并与经BglII酶切的pES-otcR骨架片段连接得到pKES-otcR。以pSF14-GFP为模板扩增gfp报告基因,该片段经NdeI和XbaI双酶切,载体骨架PermE*/kasO*/ES/KES-otcR分别经NdeI和XbaI酶切并与上述gfp片段相连得到PermE*/kasO*/ES/KES-gfp。同样pSF14-GFP经BglII和NdeI双酶切去掉SF14启动子,T4 DNA聚合酶补平缺口,由T4 DNA连接酶连接构建不含启动子只含gfp编码序列的阴性对照质粒pGT;以S.coelicolor M145基因组为模板扩增乙酰辅酶A羧化酶基因accA2和accBE两个亚基片段,并与经过NdeI和XbaI酶切PkasO*-otcR得到的骨架相连得到质粒pKaccA2BE;以pKaccA2BE为模板扩增accA2BE片段,经NheI酶切后与PkasO*-otcR相连得到质粒pKotcR-KaccA2BE。上述所有重组质粒均由英潍捷基(上海)贸易有限公司(北京分公司)进行测序验证。

| Name | Sequence (5′to 3′) | Use |

| ermE*-F | GGAAGATCTGTGCACGCGGTCGATCTTGACGG (BglII) | Construction of permE*-otcR |

| ermE*-R | CGCGGATCCTACCAACCGGCACGATTGTGC (BamHI) | |

| kasO*-F | GGAAGATCTTGTTCACATTCGAACGGTCTCTGC (BglII) | Construction of pkasO*-otcR |

| kasO*-R | CGCGGATCCAACTCCCCCAGTCCTGCACGC (BamHI) | |

| ES-F | CGCGGATCCTGCCTTGACCTTGATGAGGC(BglII) | Construction of pES-otcR |

| ES-R | CGCGGATCCCTAATCGAGTATTGATTGTAG (BamHI) | |

| KES-F | GGAAGATCTTGTTCACATTCGAACGGTCTC (BglII) | Construction of pKES-otcR |

| KES-R | GGAAGATCTAACTCCCCCAGTCCTGCACG (BamHI) | |

| GFP-F | GGAATTCCATATGCGTAAAGGCGAAGAGCTG(NdeI) | Construction of permE*/kasO*/ES/ KES-gfp |

| GFP-R | CTAGTCTAGATCATTTGTACAGTTCATCC(XbaI) | |

| accA2-F | GGAATTCCATATGCGCAAGGTGCTCATCGCC(NdeI) | Construction of pKaccA2BE |

| accA2-R | AAAGATATCTCAGTCCTTGATCTCGCAG(EcoRV) | |

| accBE-F | AAAGATATCACAGAACCACTCCACAGGAGGACCCAAATGACCGTTTTGGATGAGGCG(EcoRV) | |

| accBE-R | CTAGTCTAGATCAGCGCCAGCTGTGCGGG(XbaI) | |

| KaccA2BE-F | CTAGCTAGCTCAGCGCCAGCTGTGCGGG(NheI) | Construction of pKotcR-KaccA2BE |

| KaccA2BE-R | CTAGCTAGCTGTTCACATTCGAACGGTCTC(NheI) | |

| TestF2 | GGCTTGAAGGGAAGGTGTTTGTGC | Identification of the transformants |

| TestR2 | CCCAGGAGGACGACCTCCAGGTTGG | |

| Note:The introduced restriction sites are shown in italics | ||

1.2.2 突变株构建(接合转移操作)

按照Keith F.Chater的《链霉菌标准操作方法》进行接合转移操作[16]:将上述构建好的重组质粒转化进入供体菌E.coli ET12567/pUZ8002,挑取含有重组质粒的ET12567/pUZ8002克隆于Luria-Bertani培养基,培养至OD600=0.4~0.6(培养时添加50μg/ml卡那霉素、50μg/ml安普霉素和50μg/ml氯霉素)。收集菌体用2×YT培养基洗涤两次,并用等体积2×YT培养基重悬备用。收集培养5~8天的M4018孢子,用2×YT培养基洗涤两次,并用2×YT培养基重悬稀释至OD600=0.4~0.6,50℃水浴中热激10min,冷却至室温待用。取200μl上述转化有目的质粒的E.coli ET12567/pUZ8002和5~20μl经热激的孢子悬液进行充分混合,30℃摇床孵育萌发2h,涂布至MS固体培养基平板上。30℃培养12~14h后,每个板平铺1ml无菌水稀释的萘啶酮酸(终浓度25μg/ml)和安普霉素(终浓度为500μg/ml),30℃继续培养5~7天。待长出白色菌丝及孢子后,挑取单克隆液体发酵培养,提基因组进行PCR扩增鉴定,鉴定引物序列设计见表 2中的TestF2和TestR2。

1.2.3 突变株发酵

将预先培养好的M4018和上述构建好的突变株在MS平板上进行画线活化,30℃培养5天,铲取约2cm2菌丝块接种到内装40ml上述种子培养基的250ml三角瓶中,30℃、250r/min振荡培养1天,将所得的种子菌液按10%接种量转接到装有40ml发酵培养基的三角瓶中,30℃、250r/min振荡培养1~10天。

1.2.4 土霉素产量测定方法和标准曲线制作

吸取上述培养好的发酵液1ml,加9mol/L盐酸溶液酸化至pH=1.5~1.7(酸化时不停涡旋振荡混匀,用pH=0.5~5.0试纸测试,20~30μl),室温放置5min;12 000r/min,室温离心5min;取上清进行土霉素浓度测定,其测试原理[18]:土霉素分子中的酚羟基可与三价铁离子(Fe3+)反应生成褐色溶液,其颜色深浅与土霉素含量成正比,可在500nm下通过比色进行定量,通过土霉素标准曲线计算土霉素浓度,标准曲线测定见表 3。

| Group name | Amount of sample | ||||

| Controls | |||||

| OTC(μl) | 6 | 8 | 10 | 12 | 14 |

| 0.01mol/L HCl(μl) | 94 | 92 | 90 | 88 | 86 |

| 0.01mol/L HCl(μl) | 100 | 100 | 100 | 100 | 100 |

| Standards | |||||

| OTC(μl) | 6 | 8 | 10 | 12 | 14 |

| 0.01mol/L HCl(μl) | 94 | 92 | 90 | 88 | 86 |

| 0.05% FeCl3(μl) | 100 | 100 | 100 | 100 | 100 |

土霉素标准溶液配制:称取土霉素标准品100mg于100ml容量瓶中,加入0.1mol/L盐酸溶液10ml,使其溶解,补水至刻度线,摇匀配制终浓度为1mg/ml,4℃保存备用。取一空96孔板,空白对照组和标准样品组分别按表 3进行加样,室温放置20min,在500nm波长下测定吸光度(酶标仪BioTek, EpochTM, USA),以土霉

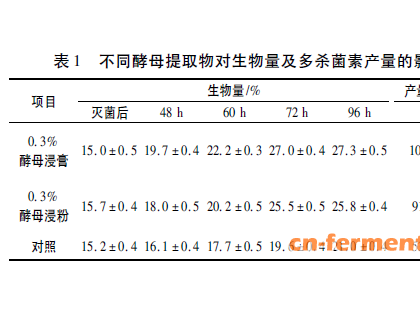

素浓度为纵坐标,以吸光度值为横坐标制作标准曲线。如图 1(a)所示,土霉素浓度计算公式y=706.87x+6.22,相关系数R2=0.999 0,土霉素浓度与吸光度呈良好的线性关系。

|

| 图 1 重组菌株土霉素产量测试 Figure 1 OTC production in the recombinant strains (a) Standard curves of OTC measured at 500nm, a linear correlation was observed over the five data points (b) OTC production was measured on the fourth day (c) OTC production was measured on the eighth day The values are means±SD from three independent experiments. M4018: the parental wild-type S. rimosus; PermE*: M4018 contains an integrated copy of otcR driven by PermE*; PkasO*: M4018 contains an integrated copy of otcR driven by PkasO*; SF14: M4018 contains an integrated copy of otcR driven by SF14; ES: M4018 contains an integrated copy of otcR driven by ES; KES: M4018 contains an integrated copy of otcR driven by KES |

|

图选项

|

1.2.5 启动子活性测试

不同启动子的转录表达活性以相对荧光表达强度(relative expression)表示,即荧光值与细胞密度(OD600)的比值(GFP/OD)表示。绿色荧光测定方法参照文献[17],将上述构建好的含有绿色荧光蛋白报告基因的突变株孢子接种到含有50ml R5培养基的三角摇瓶中,30℃、250r/min振荡培养,分别在24h、48h和96h取样测定荧光强度(酶标仪BioTek, EpochTM, USA),激发波长485nm,猝灭波长515nm。

1.2.6 丙二酸单酰辅酶A含量测定

丙二酸单酰辅酶A含量测定参考Peyraud报道的方法[20]。样品准备:构建好的突变株进行发酵培养,收集菌液,低温离心弃上清液,立即用液氮将菌体研磨至粉末;准确称量200~250mg粉末,加入1.3ml 10%(m/V)冰预冷的三氯乙酸(trichloroacetic acid,TCA),冰上涡旋3min;12 000r/min低温离心10min;取上清液加入2ml预冷乙醚(-20℃)去除TCA;收集水相并进行真空冻干,放入-80℃保存备用;所有冻干后样品分别加入0.3ml 25mmol/L甲酸铵(pH4.6,2%甲醇),溶解冻干好的粉末,0.22μm滤膜过滤取上清液进行丙二酸单酰辅酶A测试。LC-MS分析:流动相A:50mmol/L甲酸(用氨水调pH=8.1);流动相B:甲醇;C18分析柱(Gemini 150×2.0mm, particle size 3μm; Phenomenex);LC-MS(AGILENT 1200HPLC/6520QTOFMS, USA)仪器详细参数设置参考文献[20]。

1.2.7 生物量(biomass)测定方法

生物量用链霉菌菌体DNA含量来衡量,采用赵友宝报道的二苯胺(diphenylamine)测定方法进行测定[21]。测定原理:DNA在酸性条件下,其嘌呤碱与脱氧核糖之间的糖苷键断裂,生成嘌呤碱、脱氧核糖和脱氧嘧啶核苷酸,而2-脱氧核糖在酸性环境中加热脱水生成-羟基--酮基戊糖,与二苯胺试剂反应生成蓝色物质,在595nm波长处最大吸收,菌体生物量越大,其DNA含量越高,对应吸光值越大。具体操作流程如下,二苯胺试剂:称取1g二苯胺,溶于100ml分析纯的冰乙酸中,再加入1.5ml的浓硫酸,混匀待用。临用前加入1ml的1.6%乙醛,配成的试剂应为无色。收集1ml发酵液,离心去上清液后用SET缓冲液[75mmol/L NaCl、20mmol/L Tris-HCl(pH7.5)、25mmol/L EDTA(pH8.0)]洗一次,离心弃上清液;将菌体重悬于2ml二苯胺试剂中,60℃水浴1h之后离心取上清液测定OD595的吸光值。

2 结果与分析 2.1 生物信息学分析放线菌中的绝大部分途径特异性的调控因子都属于链霉菌抗生素调控蛋白(streptomyces antibiotic regulatory proteins,SARP)家族蛋白,该家族蛋白N端的特征是含有一个螺旋-转角-螺旋的结构序列(helix-turn-helix motif,HTH),HTH结构区域能够与抗生素合成靶基因的启动子区域结合,这些结合序列通常很保守(TCGAGXX),并在靶基因的启动子区形成两个或多个串联重复排列[22-24];C端为转录激活结构域(bacterial transcriptional activation domain,BTAD),高效启动靶基因的转录[4, 25]。一些氨基酸数目较多(>300)的SARP类调控蛋白的C端还有ATPase功能,如AfsR[26]。本文所选蛋白质序列均来源NCBI数据库(National Center for Biotechnology Information; http://www.ncbi.nlm.nih.gov/),利用Clustal X软件进行序列比对,分析结果如图 2所示,龟裂链霉菌土霉素合成途径特异性调控蛋白OtcR与其它已报道的SARP类蛋白均有较高的氨基酸序列相似性。例如,天蓝色链霉菌合成actinorhodin和alkaloid coelimycin P1的途径特异性调控蛋白ActII-ORF4和KasO;棒状链霉菌克拉维酸合成途径特异性调控蛋白CcaR;金色链霉菌金霉素合成调控蛋白CtcB,N端含有明显的DNA结合结构区的特征,C端含典型的BTAD结构域。前期本课题组研究证明[17]:OtcR对土霉素的生物合成起到非常关键的作用,以绿色荧光蛋白基因gfp为报告基因进行表征,在异源背景E.coli和自身M4018宿主内,OtcR蛋白均能够启动并增强土霉素合成基因簇内结构基因的转录表达。根据上述氨基酸序列的比对分析结果和前期关于OtcR功能的研究工作,本文在M4018宿主内利用不同的启动子增强OtcR转录表达,使其促进土霉素的合成。

|

| 图 2 抗生素调控蛋白OtcR、CtcB、ActII-ORF4、CcaR和KasO序列比对 Figure 2 Multiple alignment of the SARP activators OtcR, CtcB, ActII-ORF4, CcaR and KasO The predicted secondary structure of the N-terminal DNA-binding domain, including the HTH variant, is marked. The transcriptional activation domain is indicated with arrows |

|

图选项

|

本实验所使用出发载体pGusT-SF14为整合型载体,含有噬菌体φC31整合位点(attP)及其整合酶(integrase),在供体菌ET12567/pUZ8002(DNA去甲基化作用,编码合成转移酶transferase)协助下,该载体通过接合转移导入到M4018宿主内,并将整个质粒整合到宿主M4018基因组上的attB位点上。接合转移原理及突变株验证原理如图 3(a)所示,引物TestF2为上述构建好的重组质粒上一段序列,引物TestR2为出发M4018基因组上整合位点附近的一段序列,发生接合转移的突变株,经PCR扩增可得到大小1 400bp的PCR条带,阴性对照为出发株M4018,结果如图 3(b)、(c)所示,所有突变株均能扩增出预期大小的条带,接合转移操作成功,外源基因整合到M4018基因组上。

|

| 图 3 接合转移原理流程图及接和子鉴定电泳图 Figure 3 Generation and validation of the introduction of extra genes (a)Schematic diagram depicting the integration mechanism of a plasmid into the genome of M4018, aac(3)IV: apramycin resistance-conferring gene, attP: attachment site for integration, rep(pMB1): origin of replication in E.coli, integrase: integrase of phageФC3, oriT: origin of plasmid transfer (b) PCR identification of S. rimosus transformants Lanes 1-5: The transformants contain an integrated copy of otcR driven by PermE*/PkasO*/SF14/ES/KES promoter, respectively; Lane 6: wild-type S. rimosus M4018(negative control) (c) PCR identification of S. rimosus transformants containing the integrated plasmid. Lane 1: M4018/pGT contains an integrated control plasmid; Lane 2-6: The transformants contain an integrated copy of gfp driven by PermE*/PkasO*/SF14/ES/KES promoter, respectively; Lane 7: wild-type S. rimosus M4018(negative control) |

|

图选项

|

为了增强M4018土霉素合成基因簇的转录表达活性,本实验选取了链霉菌遗传操作中常用的一些组成型启动子,如SF14、PermE*和PkasO*来过表达OtcR调控蛋白,这些启动子在多种链霉菌中均表现出较强的转录活性。PermE*启动子来源红色糖多孢菌(Saccharopolyspora erythraea),原始为PermE(含有两个-35区和两个-10区)启动子,PermE*对PermE启动子的第一个-10区进行缺失突变,从而使启动子的活性显著增加[27]。Labes等[28]在噬菌体中发现SF14启动子在链霉菌中也表现普遍的转录活性,而且转录活性高于PermE*;Wang等[19]经工程改造的PkasO*启动子活性明显强于PermE*和SF14,而且证明PkasO*能够在多种链霉菌中表现普遍的转录活性。本文首先运用这三种启动子分别过表达OtcR,发酵结果显示均能显著提高土霉素产量,其中PkasO*启动子效果最为明显,与出发株M4018相比,土霉素产量提高了近4倍,产量达到5.98g/L(图 1)。为了进一步加强启动子活性,本文也初步尝试了两个启动子和三个启动子串联组合来过表达OtcR,其中PermE*和SF14串联组合成ES启动子,PkasO*、PermE*和SF14三个启动子串联组合成KES启动子。发酵检测结果显示:ES启动子过表达OtcR突变株土霉素产量低于PermE*,而KES启动子过表达OtcR的突变株土霉素产量更低[图 1(b)、(c)],推测这种简单的启动子之间的串联并不能起到增加转录活性的作用。

2.4 启动子活性评价上述发酵实验结果表明,通过启动子的串联来过表达OtcR并不能显著提高土霉素产量,反而产量低于单一启动子。为了进一步验证上述单一启动子和串联启动子的转录表达活性,以绿色荧光蛋白作为报告基因,在M4018宿主中通过荧光表达强度表征上述启动子的活性,结果如图 4所示。PkasO*启动子在24h、48h和96h均表现出较高的荧光值,表明转录表达活性明显高于PermE*和SF14,该部分结果与Wang等[19]对这三种启动子转录表达活性的评价基本一致。而串联启动子ES和KES的活性显著低于出发启动子PermE*和SF14。说明启动子之间的串联组合可能并不能起到每个启动子之间的加和作用,反而会相互影响导致活性降低。上述发酵结果说明启动子活性越强,OtcR相应的表达量越高,重组菌株土霉素产量越高。

|

| 图 4 绿色荧光蛋白表征启动子的转录表达活性 Figure 4 Quantitative analysis of the expression profiles of different promoters by gfp reporter gene in S. rimosus M4018 The values are means±SD from three independent experiments |

|

图选项

|

随着龟裂链霉菌基因组测序草图的公布[29],Pickens和Tang[13]对龟裂链霉菌土霉素合成途径的20个结构基因进行了体内和体外实验研究及酶学功能验证,全面揭示了龟裂链霉菌土霉素的分子生物合成途径。土霉素的合成是由典型II型聚酮合成酶(minina1 polyketide synthase, miniPKS)催化完成的,miniPKS由oxyA、oxyB和oxyC三个基因组成,miniPKS催化的底物是丙二酸单酰辅酶A。Rodriguez等[30]用天蓝色链霉菌证明乙酰辅酶A羧化酶(AccA2BE)能够将乙酰辅酶A转化为丙二酸单酰辅酶A。相关文献研究表明,增加链霉菌次级代谢合成的前体物或底物也能显著提高次级代谢产物的产量[31-32]。本文为了进一步提高M4018合成土霉素的产量,尝试通过过表达乙酰辅酶A羧化酶(AccA2BE)来增加M4018胞内丙二酸单酰辅酶A的含量,进而提高土霉素的产量。发酵结果如图 5所示,与出发株M4018相比,过表达乙酰辅酶A羧化酶(AccA2BE)的突变株土霉素产量提高约1.2倍。

|

| 图 5 乙酰辅酶A羧化酶过表达突变株土霉素产量测试 Figure 5 OTC production profiles of the acetyl-CoA carboxylase overexpression strains The values are means±SD from three independent experiments. M4018: Wild-type S. rimosus M4018; AccA2BE: Recombination strains contain the acetyl-CoA carboxylase integrated in the genome of M4018 |

|

图选项

|

根据上述研究结果,利用强启动子单独过表达OtcR和单独过表达乙酰辅酶A羧化酶均能不同程度的提高龟裂链霉菌M4018土霉素的产量。在此基础上,本文构建工程菌株,在M4018宿主内同时过表达OtcR和乙酰辅酶A羧化酶AccA2BE,即增强土霉素合成基因簇表达的同时,增加合成土霉素合成所需的前体物丙二酸单酰辅酶A的含量,促进底物持续转化为土霉素。重组工程菌株发酵测试土霉素产量均显著高于出发菌株M4018和单独过表达OtcR或乙酰辅酶A羧化酶重组菌,结果如图 6(a)所示,土霉素最高产量达9.09g/L;同时结合LC-MS技术分别测定了出发株M4018和工程菌株胞内丙二酸单酰辅酶A的含量,如图 6(b)所示,与出发菌株M4018相比,过表达OtcR重组菌(KotcR)胞内丙二酸单酰辅酶A含量大幅度降低,尤其在发酵后期(10天)含量达到最低值,说明胞内丙二酸单酰辅酶A大量用于土霉素的合成,而过表达乙酰辅酶A羧化酶突变株(KotcR-KaccA2BE)胞内丙二酸单酰辅酶A含量显著高于过表达OtcR重组菌(KotcR)和M4018,表明乙酰辅酶A羧化酶将胞内初级代谢合成的乙酰辅酶A更多的转化为土霉素合成的前体物丙二酸单酰辅酶A,其中一部分丙二酸单酰辅酶A用于土霉素的合成,使土霉素产量最终提高到原来的6.6倍。同时利用二苯胺方法评价了M4018和工程菌株的生长情况[图 6(c)],其生物量水平变化不大,表明工程菌株土霉素产量提高并不是由于生物量增多引起的,而是由于过表达OtcR和乙酰辅酶A羧化酶产生的。

|

| 图 6 土霉素发酵产量测试,胞内丙二酸单酰辅酶A测定及生物量评价 Figure 6 OTC production, levels of malonyl-CoA and growth curves of M4018 and the engineered recombination strains (a) OTC production profiles of M4018 and the engineered recombination strains (b) Intracellular concentration of malonyl-CoA in M4018 and the engineered recombination strains (c) Growth profiles of M4018 and the engineered recombination strains measured by the diphenylamine method The values are means±SD from three independent experiments. M4018: Wild-type S. rimosus M4018; KotcR: Recombination strains contain an integrated copy of otcR driven by PkasO*; KotcR-KaccA2BE: Recombination strains contain an integrated copy of otcR and accA2BE driven by PkasO* |

|

图选项

|

综上所述,本文采用两种策略:在土霉素生产菌株中利用强启动子过表达土霉素合成途径特异性调控蛋白OtcR和乙酰辅酶A羧化酶来提高土霉素产量。实验结果证明增强土霉素合成基因簇的转录活性的同时给予充足的前体物,最终使龟裂链霉菌合成土霉素产量提高到原来的6.6倍。在工业发酵生产中,本文所运用的工程改造策略对于改造龟裂链霉菌提高其土霉素产量提供一定的指导作用。

本文选取了文献中关于链霉菌常用的强启动子过表达OtcR蛋白来提高土霉素产量,随着启动子活性增强,其土霉素产量也越高。为了进一步提高启动子活性,本文也简单的尝试了两个启动子(ES:PermE*-SF14)和三个启动子的串联(KES:PkasO*-PermE*-SF14)来过表达OtcR蛋白,期望通过串联启动子来进一步增强转录活性,但是这些串联的启动子转录表达强度明显低于单个启动子。目前本课题组对这种启动子串联影响转录活性的现象正在做进一步的实验研究,初步认为多个启动子串连在一起含有多个-35区和多个-10区,RNA聚合酶蛋白自身比较大,可能会影响RNA聚合酶精确的识别和结合基因的启动子区,或者影响RNA聚合酶准确识别转录起始位点,导致转录效率下降,所以不如单个启动子表现的活性强;同时从生物进化的角度分析,目前原核生物绝大多数的启动子一般只含有单个-35区和单个-10区,少数基因的启动子含有两个-35区和-10区,原核生物基因组容量要明显小于真核生物,为了体现节约性,大部分原核生物基因的排列采用多顺反子形式,通常多个功能相似或相关的基因共同使用一个启动子。

近年来随着分子生物学技术的快速发展,人们对链霉菌合成次级代谢产物调控方面的研究越来越深入,链霉菌次级代谢产物合成受到多种调控因子的调节,这些调控因子主要分为3类:全局性调控因子(global regulator),通常位于调控网络的顶层,这类调控基因不但影响次级代谢合成,还影响链霉菌的生长和生理发育等行为活动;多效性调控因子(pleiotropic regulator)是指单个基因能够影响链霉菌多种不同的表型特征变化,该类调控因子通常以信号感应的形式来影响多个基因的表达;途径特异性调控因子主要调控某种次级代谢产物的合成,途径特异性调控基因直接参与次级代谢产物的合成,过表达这些基因能够显著提高抗生素产量。次级代谢产物一般在链霉菌生长后期开始合成,途径特异性调控蛋白直接负责调控次级代谢合成基因簇转录,但这些次级代谢基因簇表达也会受到环境因素或者其它基因的调控影响[33],形成错综交织的网络体系。目前业界关于这方面的研究在逐渐增多,一些转录芯片数据也逐渐开始揭示途径特异性调控基因与其它基因的调控网络关系[4, 34],因此关于这方面的研究仍然是今后研究的热点和重点。

致谢 感谢华东理工大学郭美锦教授馈赠S.rimosus M4018菌株,感谢中国科学院微生物研究所艾国民老师和李珊珊博士后在提取和分析胞内丙二酸单酰辅酶A方面提供的帮助。| [1] | 李寅. 代谢工程:一项不断发展的菌株改造技术. 生物工程学报 , 2009, 25 (9) : 1281–1284. Li Y. metabolic engineering:an evolving technology for strain improvement. Chinese Journal of Biotechnology , 2009, 25 (9) : 1281–1284. |

| [2] | 张红岩, 辛雪娟, 申乃坤, 等. 代谢工程技术及其在微生物育种的应用. 生物技术通报 , 2012, 39 (4) : 17–21. Zhang H Y, Xin X J, Sheng N K, et al. Application of metabolic engineering in strain breeding industrial microbe. Biotechnology Bulletin , 2012, 39 (4) : 17–21. |

| [3] | 李寅, 曹竹安. 微生物代谢工程:绘制细胞工厂的蓝图. 化工学报 , 2004, 55 (10) : 1573–1580. Li Y, Cao Z A. Microbial metabolic engineering:gateway to develop blueprints for cell factories. Journal of Chemical Industry and Engineering (China) , 2004, 55 (10) : 1573–1580. |

| [4] | Liu G, Chater K F, Chandra G, et al. Molecular regulation of antibiotic biosynthesis in Streptomyces. Microbiol Mol Biol Rev , 2013, 77 (1) : 112–143. DOI:10.1128/MMBR.00054-12 |

| [5] | Takano E, Gramajo H C, Strauch E, et al. Transcriptional regulation of the redD transcriptional activator gene accounts for growth-phase-dependent production of the antibiotic undecylprodigiosin in Streptomyces coelicolor A3(2). Mol Microbiol , 1992, 6 (19) : 2797–2804. DOI:10.1111/mmi.1992.6.issue-19 |

| [6] | Fujii T, Gramajo H C, Takano E, et al. redD and actⅡ-ORF4, pathway-specific regulatory genes for antibiotic production in Streptomyces coelicolor A3(2), are transcribed in vitro by an RNA polymerase holoenzyme containing sigma hrdD. J Bacteriol , 1996, 178 (11) : 3402–3405. |

| [7] | Jnawali H N, Lee H C, Sohng J K. Enhancement of clavulanic acid production by expressing regulatory genes in gap gene deletion mutant of Streptomyces clavuligerus NRRL3585. J Microbiol Biotechnol , 2010, 20 (1) : 146–152. |

| [8] | Guo D, Zhao Y, Yang K. Coordination of glycerol utilization and clavulanic acid biosynthesis to improve clavulanic acid production in Streptomyces clavuligerus. Sci China Life Sci , 2013, 56 (7) : 591–600. DOI:10.1007/s11427-013-4507-z |

| [9] | Butler M J, Bruheim P, Jovetic S, et al. Engineering of primary carbon metabolism for improved antibiotic production in Streptomyces lividans. Appl Environ Microbiol , 2002, 68 (10) : 4731–4739. DOI:10.1128/AEM.68.10.4731-4739.2002 |

| [10] | Tang Z, Xiao C, Zhuang Y, et al. Improved oxytetracycline production in Streptomyces rimosus M4018 by metabolic engineering of the G6PDH gene in the pentose phosphate pathway. Enzyme Microb Technol , 2011, 49 (1) : 17–24. DOI:10.1016/j.enzmictec.2011.04.002 |

| [11] | 廖瑜玲, 刘志勇, 唐振宇, 等. 龟裂链霉菌zwf2基因敲入及阻断对土霉素合成的影响. 食品与药品 , 2009, 11 (1) : 7–10. Liao Y L, Liu Z Y, Tang Z Y, et al. Disruption of zwf2 gene to improve oxytetraclyline biosynthesis in Streptomyces rimosus M4018. Food and Drug , 2009, 11 (1) : 7–10. |

| [12] | 尹守亮, 常亚婧, 邓苏萍, 等. 以病原菌群体感应系统为靶标的新型抗菌药物的研究进展. 药学学报 , 2011, 46 (6) : 613–621. Yin S L, Chang Y J, Deng S P, et al. Research progress of new antibacterial drugs that target bacterial quorum sensing systems. Acta Pharmaceutica Sinica , 2011, 46 (6) : 613–621. |

| [13] | Pickens L B, Tang Y. Oxytetracycline biosynthesis. J Biol Chem , 2010, 285 (36) : 27509–27515. DOI:10.1074/jbc.R110.130419 |

| [14] | Yu L, Cao N, Wang L, et al. Oxytetracycline biosynthesis improvement in Streptomyces rimosus following duplication of minimal PKS genes. Enzyme Microb Technol , 2012, 50 (6) : 318–324. |

| [15] | Chu X, Zhen Z, Tang Z. Introduction of extra copy of oxytetracycline resistance gene otrB enhances the biosynthesis of oxytetracycline in Streptomyces rimosus. Journal of Bioprocessing&Biotechniques , 2012, 2 (3) : 1–4. |

| [16] | Kieser T BM, Buttner M J, Chater K F, et al. Practical Streptomyces Genetics. 2nd ed Norwich, UK: The John Innes Foundation, 2000 : 289 -295. |

| [17] | Yin S, Wang W, Wang X, et al. Identification of a cluster-situated activator of oxytetracycline biosynthesis and manipulation of its expression for improved oxytetracycline production in Streptomyces rimosus. Microb Cell Fact , 2015, 14 (46) : 1–12. |

| [18] | 齐广辉, 杨俊青, 田莉瑛, 等. 几种诱变因子对龟裂链霉菌的诱变效果. 河北师范大学学报(自然科学版) , 2013, 37 (4) : 402–409. Qi G H, Yang J Q, Tian L Y, et al. Mutagenic effects of several mutagenic factors on Streptomyces rimosus. Journal of Hebei Normal University (Nature Science Edition) , 2013, 37 (4) : 402–409. |

| [19] | Wang W, Li X, Wang J, et al. An engineered strong promoter for Streptomycetes. Appl Environ Microbiol , 2013, 79 (14) : 4484–4492. DOI:10.1128/AEM.00985-13 |

| [20] | Peyraud R, Kiefer P, Christen P, et al. Demonstration of the ethylmalonyl-CoA pathway by using 13C metabolomics. Proc Natl Acad Sci USA , 2009, 106 (12) : 4846–4851. DOI:10.1073/pnas.0810932106 |

| [21] | Zhao Y, Xiang S, Dai X, et al. A simplified diphenylamine colorimetric method for growth quantification. Appl Microbiol Biotechnol , 2013, 97 (11) : 5069–5077. DOI:10.1007/s00253-013-4893-y |

| [22] | Mizuno T, Tanaka I. Structure of the DNA-binding domain of the OmpR family of response regulators. Mol Microbiol , 1997, 24 (3) : 665–667. DOI:10.1046/j.1365-2958.1997.3571723.x |

| [23] | Martinez-Hackert E, Stock A M. The DNA-binding domain of OmpR:crystal structures of a winged helix transcription factor. Structure , 1997, 5 (1) : 109–124. DOI:10.1016/S0969-2126(97)00170-6 |

| [24] | Tsung K, Brissette R E, Inouye M. Identification of the DNA-binding domain of the OmpR protein required for transcriptional activation of the ompF and ompC genes of Escherichia coli by in vivo DNA footprinting. J Biol Chem , 1989, 264 (17) : 10104–10109. |

| [25] | Chen Y, Wendt-Pienkowski E, Shen B. Identification and utility of FdmR1 as a Streptomyces antibiotic regulatory protein activator for fredericamycin production in Streptomyces griseus ATCC 49344 and heterologous hosts. J Bacteriol , 2008, 190 (16) : 5587–5596. DOI:10.1128/JB.00592-08 |

| [26] | Tanaka A, Takano Y, Ohnishi Y, et al. AfsR recruits RNA polymerase to the afsS promoter:a model for transcriptional activation by SARPs. J Mol Biol , 2007, 369 (2) : 322–333. DOI:10.1016/j.jmb.2007.02.096 |

| [27] | Bibb M J, Janssen G R, Ward J M. Cloning and analysis of the promoter region of the erythromycin resistance gene (ermE) of Streptomyces erythraeus. Gene , 1985, 38 (1) : 215–226. |

| [28] | Labes G, Bibb M, Wohlleben W. Isolation and characterization of a strong promoter element from the Streptomyces ghanaensis phage I19 using the gentamicin resistance gene (aacC1) of Tn 1696 as reporter. Microbiology , 1997, 143 (5) : 1503–1512. DOI:10.1099/00221287-143-5-1503 |

| [29] | Pethick F E, Macfadyen A C, Tang Z, et al. Draft Genome Sequence of the Oxytetracycline-Producing Bacterium Streptomyces rimosus ATCC 10970. Genome Announc , 2013, 1 (2) : e0006313. |

| [30] | Rodriguez E, Banchio C, Diacovich L, et al. Role of an essential acyl coenzyme A carboxylase in the primary and secondary metabolism of Streptomyces coelicolor A3(2). Appl Environ Microbiol , 2001, 67 (9) : 4166–4176. DOI:10.1128/AEM.67.9.4166-4176.2001 |

| [31] | Cardenas J, Da Silva N A. Engineering cofactor and transport mechanisms in Saccharomyces cerevisiae for enhanced acetyl-CoA and polyketide biosynthesis. metab Eng , 2016, 36 (07) : 80–89. |

| [32] | Zabala D, Brana A F, Salas J A, et al. Increasing antibiotic production yields by favoring the biosynthesis of precursor metabolites glucose-1-phosphate and/or malonyl-CoA in Streptomyces producer strains. J Antibiot (Tokyo) , 2015, 10 (1) : 1–4. |

| [33] | 尹守亮, 张玉秀, 张琪, 等. 无机磷酸盐对链霉菌合成次级代谢产物的影响. 中国生物工程杂志 , 2015, 35 (9) : 105–113. Yin S L, Zhang Y X, Zhang Q, et al. The effect of inorganic phosphate on the biosynthesis of secondary metabolites in Streptomyces. China Biotechnology , 2015, 35 (9) : 105–113. |

| [34] | Allenby N E, Laing E, Bucca G, et al. Diverse control of metabolism and other cellular processes in Streptomyces coelicolor by the PhoP transcription factor:genome-wide identification of in vivo targets. Nucleic Acids Res , 2012, 40 (19) : 9543–9556. DOI:10.1093/nar/gks766 |